Telehandler Safety Tips

The telehandler is a robust and adaptable machine that can drastically increase job site productivity. A telehandler is one of the most versatile pieces of equipment on a construction site. The value of this machine lies in its ability to serve multiple purposes — whether you need to move, lift or place loads in specific locations, it’s an excellent choice since it’s equipped to meet more than one work site demand.

As telehandler operators learn how to accomplish more and more on their job sites with this equipment, they can follow these easy tips and best practices on the safe use of telehandlers in construction to minimize the chance of accidents. Observing telehandler safety procedures will help limit the occurrence of mishaps and keep the machine functioning successfully from one application to another.

12 Tips for Operating a Telehandler Safely

With all of the telehandler’s advantages come some particular safety concerns. Here are 12 tips on the safe use of telehandlers that business owners and operators can reference to build a complete telehandler safety checklist:

1. Require Telehandler Training

All telehandler operators must receive thorough training on the specific model they’ll be operating. Occupational Safety and Health Administration (OSHA) requirements on powered industrial trucks require that training include a combination of formal instruction, practical application of concepts and an evaluation of the operator’s performance in the workplace. Incorporating these elements ensures a comprehensive experience and helps promote a safety-first mindset.

2. Perform Inspections

Before even turning on the machine, it’s essential to perform a pre-operation inspection and function testing. A telehandler safety inspection checklist is a handy tool to ensure that all components are working correctly. While working through the list, the operator should take notes if any telehandler components or systems appear faulty and promptly remove the machine from further service. Any required repairs should be performed by a professional.

3. Consult Load Charts

Don’t use a telehandler without first consulting a load capacity chart. Before lifting anything, ensure the specific telehandler’s load chart matches your equipment and attachments and that it is readily legible and visible to the operator while the machine is in use.

Never try to lift a load that exceeds the telehandler’s maximum weight, as doing so may cause the telehandler to tilt and tip over. Most telehandlers include a safety system that stops them from lifting loads that are too heavy, but users should still find the maximum weight of the telehandler in its manual rather than relying on these features.

4. Know the Load

In addition to referencing the load charts, you need to know the loads the telehandler will carry and transport. Each load that the machine will carry will differ and pose new challenges. As such, we recommend consistently checking the load chart to ensure that the load’s weight and center of gravity are appropriate for the telehandler and its attachment. Determine suitable handling strategies by evaluating the size of the load, and always secure loads properly to reduce the possibility of falling debris.

5. Observe the Stability Triangle

Unbalanced loads can lead to telehandler accidents, so each operator must be familiar with the stability triangle. Maintain the combined center of gravity of the telehandler and the load inside the stability triangle at all times. Good operational practices that might be beneficial include:

- Before managing a load, ensure the chassis is level. Never utilize the sway function with an elevated load.

- During travel, keep the boom as low as possible.

- Only move at speeds that allow you to keep the machine and the load under control at all times.

6. Conduct Hazard Assessments

Before transporting the telehandler to the job site, perform a workplace hazard assessment. Just as each load will pose new challenges, so will the project’s site of operation and the journey toward it. Avoid risks such as drop-offs and holes, slippery or unstable surfaces, slopes, power lines, overhead barriers and any other potential hazards that may present themselves. If any obstacles appear, develop a strategy to avoid these hazards during all phases of the telehandler’s operation.

7. Maintain Cab Safety

Although telehandlers don’t necessarily move fast, a telehandler operator must always wear their seatbelt. Operating a telehandler safely requires cab safety measures as well — including wearing a seatbelt that minimizes the risk of injury or death in an accident, especially during a tip-over. Operators can also adjust the seat and steering wheel to make all machine controls conveniently accessible. Before each use, they should set the side and cab mirrors for optimal field of vision.

8. Know Tipping Safety Procedures

What does one do if the telehandler tips over? First, operators should resist the urge to jump off the machine. They need to stay in the cab and brace for impact by holding on to the steering wheel, supporting themselves with their feet and leaning away from the point of impact. Keep these pointers in mind and telehandler operators can minimize the risk of injury when operating a telehandler on any project.

9. Learn Rules and Regulations

Just as each operator needs proper training, they also need to know all applicable rules and regulations. Before operating the telehandler, operators must read, understand and respect the employer’s safety standards and job site regulations, as well as all relevant municipal, governmental or provincial legislation regarding the safe use of telehandlers.

10. Follow Guidance on Personnel and Suspended Loads

When using a telehandler to hoist personnel or suspend loads, remember that these tasks involve extra constraints for the operator and the business owner. Know the additional requirements and operating instructions for these applications — refer to the ANSI/ITSDF B56.6 standard, OSHA telehandler safety regulations, and the telehandler and attachment manufacturer’s instructions.

11. Know the Terrain

Even without a load, a telehandler may weigh more than 25,000 pounds. The force that these machines exert on the ground is enormous, so operators must be sure they know the terrain on and around the project’s site. Telehandlers can get stuck in mud or soft soil if moved without care, resulting in a loss of precious work time. The only solution to prevent these issues is to be aware of one’s surroundings and the specific characteristics of the terrain.

12. Adjust Driving Behavior

Telehandlers typically move more slowly than some other machines. They may reach a speed of up to 25 miles per hour when driving on highways, but this is not the case on building sites. Telehandler operators must adjust their speed to specific conditions, particularly on uneven terrain, to maintain control of the machine.

Operators should always consider both the terrain and the load when moving. Centrifugal force comes into play during cornering, which means that materials under transport are attracted to the turn’s rim. Telehandler operators should never start, stop or abruptly change directions, especially at high speeds. These abrupt motions might cause the telehandler to lose its load or tilt. Additionally, users should always go up and down slopes in a controlled and reasonable manner.

Telehandler Best Practices

This safety checklist for telehandler operation includes best practices for supervisory personnel as well as operators.

Pre-Operation

Observing pre-operation best practices is the most crucial part of operating a telehandler. Inspecting the environment, the personnel, and the necessary machinery and equipment can help maintain the safety of everyone involved.

Pre-operation checklist for supervisory personnel:

- Inspect machinery and equipment: Ensure that the machinery and equipment chosen are suitable for the project. For specific operational or equipment requirements, consult the operator handbook. To ensure safe operation, know the appropriate OSHA standards.

- Set up an emergency action plan: Ensure that an effective emergency action plan is in place to safeguard workers in the event of a fire or natural disaster. Each project’s strategy should be site-specific and conveyed to all personnel.

- Conduct a hazard assessment: The operator and supervisory personnel must conduct a hazard assessment. Overhead wires, excavations, traffic and work zones are examples of site-specific hazards.

- Supply protective equipment: Ensure that proper personal protective equipment (PPE) is available for the job as required by OSHA standards.

- Check fire extinguishers: Check the position of the fire extinguisher and ensure it’s functional and fully charged.

- Use only qualified operators: Confirm that all operators have received the necessary training to use the equipment present.

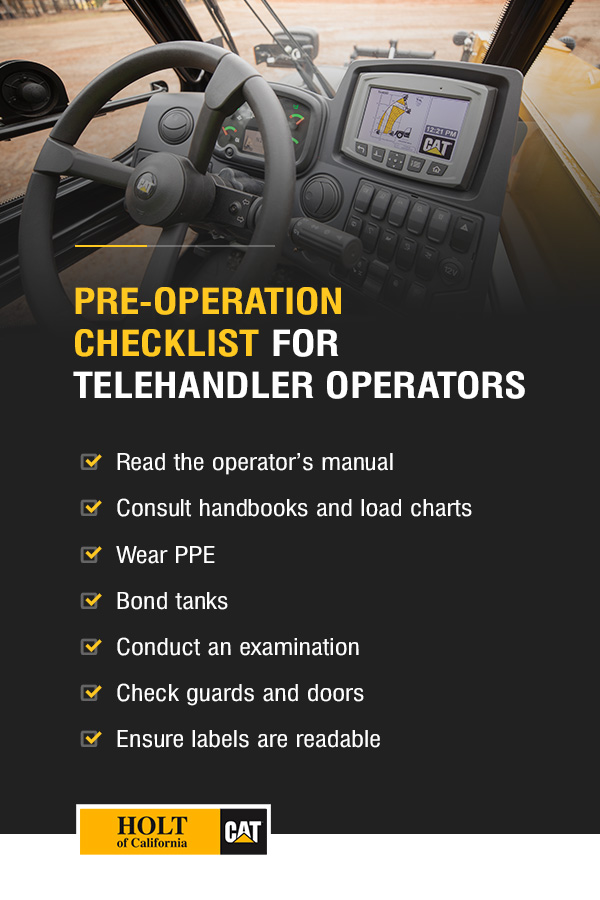

Pre-operation checklist for operators:

- Read the operator’s manual: Telehandler operators must read, comprehend and adhere to the specific telehandler model’s manual.

- Consult handbooks and load charts: To assess the operational capabilities of the telehandler, consult the handbook and load charts installed on the equipment. Stay within the equipment’s recommended capacities.

- Wear PPE: Wear the proper PPE for the duties at hand and as required by OSHA standards.

- Bond tanks: Bond the supply tank with the gasoline tank during refilling to avoid static discharge and fire.

- Conduct an examination: Conduct and document a walk-around examination, checking all fluids and noting any components that require maintenance or repair. Ensure all critical repairs are completed before operation and documented in the maintenance record per corporate policy.

- Check guards and doors: Check that all guards and access doors are in place and operational.

- Ensure labels are readable: Ascertain that all warning plates and labels are readable. If the operator’s signature needs to be legible or present, they must notify the supervisor or corporate employees for replacement.

- Declutter the cab: Remove any debris or clutter that may jeopardize safe operation.

- Check fire extinguishers: Check the position of the fire extinguisher and ensure it’s ready for use if needed.

- Enter the cab: Only use the machine where there are steps and handholds. If the machine lacks them, notify your supervisor immediately.

- Be careful with controls: Don’t use any controls as handholds when entering or departing the operator compartment.

- Check driving components: Check the functionality of the telehandler’s lights, horn, backup alarm, parking brake and seatbelt.

- Check controls: Before starting the machine, ensure that the controls are in the proper startup position.

Operation

During the operation of a telehandler, there are a few things that the operator and the supervisory personnel need to consider.

Operation checklist for supervisory personnel:

- Qualified operator: Only an appropriately trained and assessed telehandler driver is qualified and permitted to operate the machine.

- Unnecessary personnel: Check that any unneeded employees and equipment are out of the work area.

- Necessary personnel: Ensure that one designated person issues signals at a time and that all relevant personnel on-site understand them. Communication should be addressed during the pre-employment evaluation.

Operation checklist for operators:

- Qualified operator: If a worker is uncomfortable or does not feel adequately trained, they should not operate the telehandler.

- Designate a spotter: If there are overhead electrical lines or space constraints in the work area, a competent individual and supervisor must designate a certified spotter. Obey all OSHA standards related to overhead electrical risks.

- Keep doors locked: When the equipment is in use, any doors must be closed or locked in the open position by a latch.

- Exiting the machine: If the operator leaves, lower the boom, engage the parking brake and turn off the machine.

- Keep personnel clear from telehandler: Allow no one to stand or pass beneath the raised portion of any machine. Personnel should not be allowed to stand on forks. When removing loads from equipment, keep all people away from it.

- Exercise extreme caution: Handle hanging, high, long or broad weights with extreme caution. Avoid overloading and dangerous practices.

- Utilize a load extension: When supporting a load, use a load back/rest extension. Adjust the forks or attachment and fully engage the load for optimal support.

- Practice caution when driving: Before turning or moving, always lower the boom and watch for overhead obstacles. Keep a safe distance from electric lines, people, potholes and roadblocks. Always have a clear vision of the path of travel, sticking to the specified pathways and avoiding terrain that cannot properly hold the equipment. Slow down and take additional precautions when passing through low-visibility areas.

- Understand signals: All personnel must be able to understand the provided signals.

- Notice emergencies: In an emergency, all staff on site can use stop work authority to halt activity.

- Take note of weather changes: Don’t operate a telehandler in rough weather. Seek refuge following the company’s emergency action plan.

Post-Operation

Post-operation practices are another essential element of telehandler safe work procedures.

Post-operation checklist for supervisory personnel:

- Inspect machinery and equipment brakes: Check that the machine is correctly parked and the parking brake is engaged.

Post-operation checklist for operators:

- Set controls: Set the parking brake and the gearbox selection to park or neutral. For any further equipment-specific instructions, see the operator’s manual.

- Check boom and attachment: Before leaving the operator’s cab, be sure the boom has been fully retracted and lowered and the attachment is safely on the ground.

- Exit the cab: Turn off the telehandler’s engine, remove the key, lock the doors and activate any security systems present.

Contact Holt of California for Quality Telehandlers and Support

Having the appropriate piece of equipment will have a tremendous impact on the outcome of your project. Choose Caterpillar as your trusted manufacturer when you require dependable, high-performing construction machinery and equipment like telehandlers. At Holt of California, we’re an elite supplier of new Cat® telehandlers and other construction machinery and equipment. Our experts can advise you on Cat telehandler safety practices and ensure your equipment complements your applications.

We have been partnering with clients for over 90 years, providing equipment solutions and the finest product support in the business. Holt of California has built its reputation as a leader by putting our people at the center of all we do. Contact us for telehandler sales, support and service to give your operators the resources they need to work safely and efficiently.

Additional Resources on Material Handling Equipment: